Electrolux Streamlines Its Creative Process With Wrike

Global Headquarters

Stockholm, Sweden

Industry

Home appliances

# of Users

25

Website

Top Challenges

Lack of efficient processes, cross-department collaboration, visibility, and a single repository for all assets

Department Using Wrike

Packaging design department

Why Wrike

A platform to manage packaging design processes with ease

Feature Highlights

Integrations

CAD, Adobe CC

As a globally recognizable appliance brand, Electrolux has designed and manufactured over 250 luxury home appliances for a wide-ranging customer base. Established in Sweden over a century ago, Electrolux produces appliances for its own named brand as well as for AEG, Frigidaire, Zanussi, Tappan, Kelvinator, Gibson, Anova, Westinghouse and other appliance brands. The company employs 51,000 people around the world and is known for leading the industry in quality, longevity, innovation, and sustainability.

30%

less time spent per project

50%

fewer emails for the design team

The challenge

The global packaging design team at Electrolux needed a better way to manage the process of creating, adjusting, and approving packaging from start to finish. They needed software that would allow them to eliminate time-consuming admin work so they could focus more time on creation of assets.

The packaging design team had been using a cumbersome process of collecting necessary task information from a variety of places, which was wasting their team’s valuable time.

“We were getting info in emails, PowerPoints, chat functions, meetings, Excel files, and on Post-its,” Global Packaging Manager Ella Rudebeck explains. “It was really hard to keep track of all the changes if you had to look through different email chains or if you weren’t in a meeting where a decision was made. We just felt the whole process was very ineffective.”

“When we email back and forth with design comments, it takes a long time and causes a lot of mistakes,” recounts Johan Alm, Design Coordinator.

The team knew they’d benefit from an online work management platform, and Rudebeck recalls: “We wanted to have something that was more transparent, more efficient.”

The solution

“We were looking into different kinds of programs, several similar to Wrike, and we wanted something that would work for us as a packaging team,” says Rudebeck. “We were not only looking for timelines and request forms, we wanted complete transparency.”

After assessing other solutions, the packaging design team at Electrolux chose Wrike’s powerful work management software to create a single, accessible location for all project documentation, automate workflows to drive project progress, and enable transparency across complex projects.

“Overall, the functions of Wrike are helping our team. It’s such an easy and efficient tool for us.”

Johan Alm, Design Coordinator, Electrolux

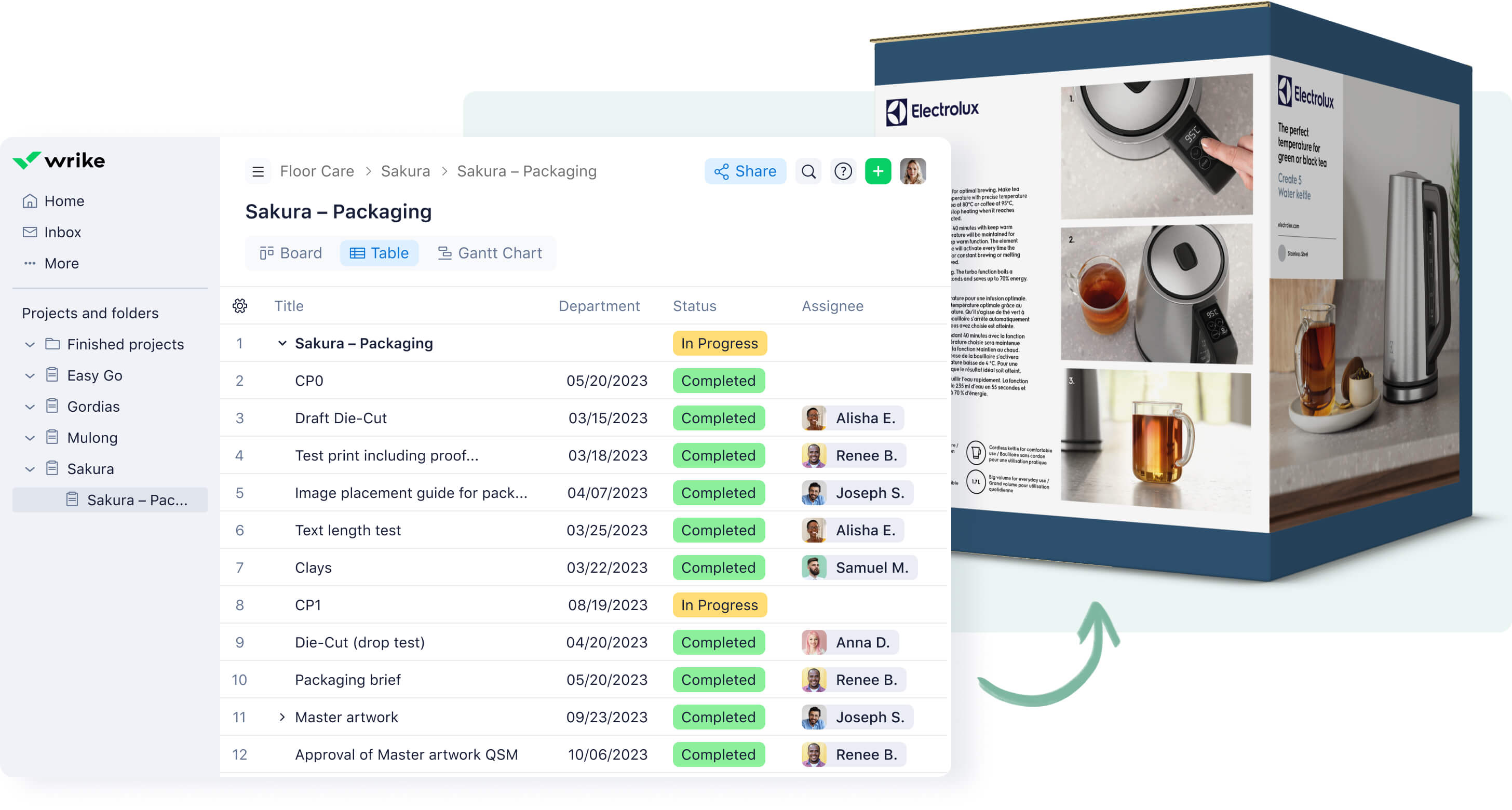

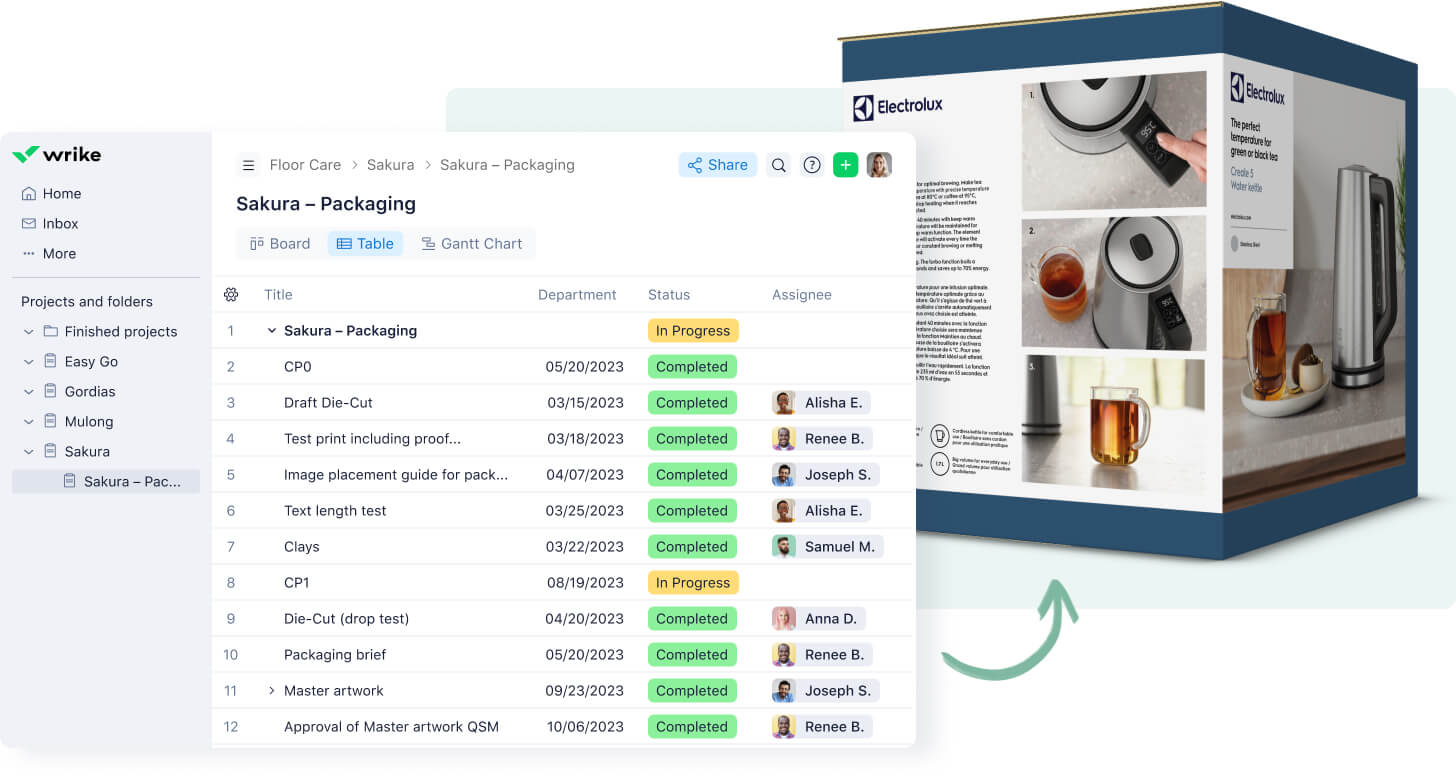

A single, transparent location for all documentation

As a creative team managing a range of assets for multiple projects at once, determining task requirements and gathering initial information was a time-consuming process that could hold up designers. The Electrolux team needed a work management solution that would add transparency to their processes and serve as a single location where all project information, requirements, and assets could be stored and searched.

Rudebeck reflects on how this has helped their entire team: “Everyone can see all the files all the time so no one has to ask to see the files via email or chat, and you automatically know if someone has uploaded a new file.”

Alm added: “It’s also time-efficient for us to have all the necessary information and material for our projects in one place. As the manager, I can assign people to every task, and it’s clear for everyone what kind of action they need to take with each project. They know when the deadline is, what they need to do; they can see the timeline in the Gantt chart as well. For a person who isn’t good at planning their work, Wrike will help them see what they need to do and when they need to deliver and where they need to find the information.”

Automated workflows and request forms

The team members rely on three bespoke Wrike Blueprints that reflect three different workflows depending on the size of each project. They have also recently begun using a customized request form that will help them acquire the information they need from other teams to kick off their own design projects. “We have built our processes in blueprints and we make our choice depending on how big the project is, with different tasks and different timelines,” Alm explains.

Having tasks that are automatically created from their team’s blueprints also enables better communication within the team. Rudebeck explains: “We have decreased the amount of emails sent to each other because we’re communicating via Wrike now. It’s fewer emails between everyone, and at least 50% fewer emails for designers.”

The packaging design team has also actively worked to bring information and communication about tasks into a single source of truth, Rudebeck says. “We have everything connected because we ask people to put it in Wrike.”

In-app proofing and approval tools

As a creative team charged with designing up to 40 assets per project, the Electrolux packaging design team was spending a lot of time fielding feedback from various sources.

Alm explains that their process relies heavily on stakeholder feedback. “A big part of our work is that we need to create layouts for the packaging and there are a lot of stakeholders that need to comment, approve, review, and make changes required.” Wrike has provided a solution that would allow them to manage all of those comments, implement them or ask questions directly on the asset, and keep approvals in one place. “When we email back and forth with design comments, it takes a long time and causes a lot of mistakes,” Alm says. “Now we can review the design layout straight in the program and our designers love it.”

The Electrolux team also regularly utilizes the guest approver functionality. Alm confirms: “Wrike is really good in that we can have guest approvers look at the artwork and give us comments directly in Wrike.” This streamlined proofing and approvals process has contributed to spending 30% less time on each project.

“Our designers really like it — they are less stressed because they have more control of the artwork.”

Ella Rudebeck, Global Packaging Manager, Electrolux

The conclusion

Over the last five years, Wrike’s collaborative work management platform has helped Electrolux’s packaging design team cut emails in half, eliminated the stress of constantly searching for information to start projects and approvals to close them out, and enabled them to produce up to 10 times as many assets per project.

Wrike has also facilitated better cross-departmental collaboration, actively improving work for Electrolux’s marketing department by housing all creative packaging assets in a single, accessible location.

Wrike has even enabled the packaging design team to improve what they can create for each project they work on. “We may take on the same amount of projects, but now we’re doing more in each project; where we had four artworks per project, now we can do 40 artworks in one project,” Rudebeck explains.

“When you have this kind of program it reduces stress for everyone involved because you can always go to the source and find it; you know where to go to look for files, you can chat with people and ask questions,” says Rudebeck. “It’s better for everyone.”

Find out how Wrike can help your business

Schedule some time to talk with one of our experts.